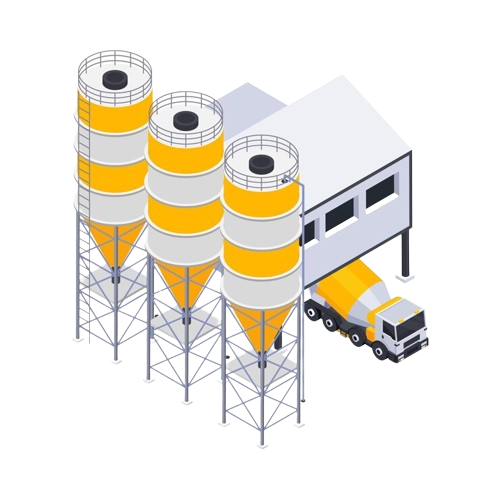

EHS Safety solution for Cement Industry

At EHS4Safety, we're dedicated to transforming safety protocols in the cement industry through our innovative Environment, Health, and Safety (EHS) software powered by Artificial Intelligence (AI). Our advanced solutions are tailored specifically to address the unique challenges faced by cement manufacturers, ensuring a safer and more efficient workplace environment.

Our advanced solution

Revolutionize Cement Industries with Cutting-edge EHS and AI Solutions

EHS Safety Compliance

Transform safety protocols in cement manufacturing with our cutting-edge Environment, Health, and Safety (EHS) solution. Designed specifically for the unique challenges of cement industries, our EHS software ensures compliance, mitigates risks, and fosters a culture of safety. Streamline incident reporting, automate compliance checks, and gain actionable insights to enhance workplace safety.

AI technology solution

AI-driven safety systems monitor workplace activities, detect hazards, and provide proactive alerts to prevent accidents, ensuring a safer working environment for employees. By leveraging AI technology, cement manufacturers can achieve higher productivity, lower costs, and improved safety standards.

Why choose Ehs4Safety?

Our Special Features

Our Trusted Client