Introduction:

Oil and gas operations involve many daily risks, making it one of the most dangerous industries for workers.. From handling flammable materials to working in confined spaces and high-pressure environments, the risks are substantial. Within manufacturing units that deal with oil and gas operations, ensuring worker safety while maintaining operational efficiency is a top priority. One of the most effective tools enabling this balance is Permit to Work (PTW) software.

Understanding Permit to Work Systems

A Permit to Work system is a written process that helps control dangerous jobs by making sure all safety steps are followed before work begins. This includes hot work, Cold Work Permit confined space entry, working at heights, and more. In traditional systems, permits are issued and managed manually, often resulting in delays, errors, and compliance gaps.

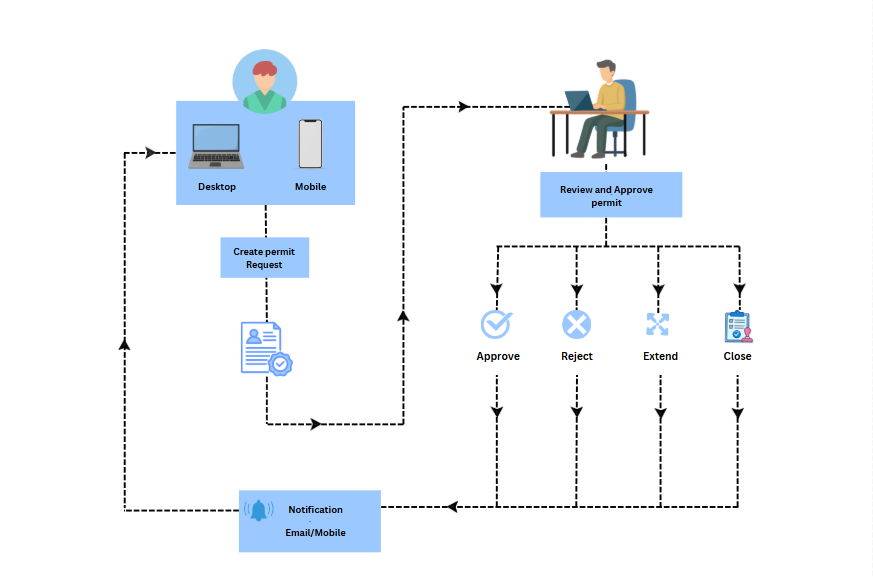

Modern Permit to Work software automates the process, offering a digital platform for creating, issuing, tracking, and closing permits. It ensures that all safety measures, approvals, and documentation are in place before any high-risk task begins.

Types of Permits in Oil & Gas PTW Software

The PTW Software uses different types of permits to address specific kinds of work that have inherent risks. Some of the main permits include .

Hot Work Permit

This permit is required for tasks involving open flames, sparks, or high temperatures such as welding, cutting or grinding. Because these activities can easily ignite flammable substances, strict controls must be in place.

Cold Work Permit

Cold work involves activities that do not generate heat or sparks, like painting, mechanical maintenance, or material handling. Even though these tasks are less risky, the permit ensures safety protocols are followed.

Work at Height Permit

For any work performed above 2 meters, such as on elevated work platforms, ladders, or roofs, a specific permit is issued to manage risks of falls and injuries.

Confined Space Entry Permit

Confined spaces, like tanks, vessels, or chamber hazards such as low oxygen, toxic gases, or restricted movement. This permit ensures that entry is controlled, monitoring is in place, and emergency procedures are prepared.

Excavation Work Permit

Excavation carries risks of cave-ins, underground utilities damage, and exposure to hazardous materials. Before digging starts, a permit helps plan the work safely and makes sure all teams are working together.

Chemical handling Permit

Chemical handling permits helps make sure dangerous chemicals are handled safely during work like drilling, processing, and maintenance. It helps prevent spills, fires, and health risks, while making sure safety and environmental rules are followed.

Why Oil & Gas Operations in Manufacturing Need PTW Software

1. High-Risk Work Requires Stringent Control

Oil and gas manufacturing involves critical processes like refining, petrochemical production, and gas processing—all of which are prone to fire, explosion, or environmental hazards. PTW software provides real-time oversight of hazardous tasks, ensuring all risk mitigation steps are followed before work begins.

2. Following Safety Rules Made Easy

Important safety groups like OSHA, ISO, and local authorities have strict rules to protect workers. Permit to Work software helps factories follow these rules by keeping everything recorded—like who gave approval, when it was given, and what safety steps were taken. This makes safety inspections easier and shows that the company is doing things the right way.

3. Improved Communication and Coordination

In a manufacturing setup, multiple departments—maintenance, safety, operations—must work in sync. PTW software creates a centralized platform where relevant stakeholders can view the status of active permits, upcoming tasks, and risk controls. It ensures no task begins without necessary cross-departmental approvals, avoiding miscommunication and delays.

4. Faster Permit Approval and Execution

Manual permit processes are time-consuming and prone to human error. With PTW software, permits can be generated, submitted, and approved digitally—reducing downtime and enhancing productivity.The system sends timely alerts and reminders to make sure tasks don’t get stuck or delayed.

5. Real-Time Monitoring and Risk Assessment

Advanced PTW software integrates with risk assessment tools and IoT-based monitoring systems. For example, in oil and gas manufacturing, sensors can detect gas leaks or fire risks and automatically trigger alerts or stop work. This data can feed into the permit system, updating risk levels and requiring additional safety checks before resuming work

LOTO Integration in PTW Software: Dual Authorization for Safety

One of the most critical aspects of safe maintenance work is Lockout/Tagout (LOTO)—a standardized procedure that ensures machines are safely de-energized and isolated before any servicing or maintenance begins. In high-risk industries like oil and gas manufacturing, LOTO procedures often require multiple personnel from different departments to verify that safety protocols have been correctly followed.

Key LOTO Integration Features in PTW Software:

1. Two-Person Authorization System

Modern Permit to Work (PTW) software supports dual-level LOTO approvals, enhancing oversight and safety.

- The first person (e.g., a maintenance supervisor) initiates the lockout.

- The second person (e.g., a safety officer or operations manager) must verify and confirm the lockout before any work can proceed.

This cross-checking mechanism helps prevent human error, ensures proper isolation of energy sources, and reinforces accountability.

2. LOTO Checklist Integration

Each permit type—especially those involving confined space entry or equipment maintenance—can include LOTO checklists embedded within the PTW system. These checklists guide personnel through essential steps such as:

- Energy source identification and isolation

- Placement of lockout tags

- Lock confirmation and verification

- Release procedures after job completion

These digital checklists help standardize processes and reduce the likelihood of missed steps.

3. Digital Lockout Records

All LOTO actions are digitally logged within the PTW system, including:

- Who initiated and verified each lockout

- Timestamps for lock placement and removal

- Details of energy sources isolated

This ensures complete traceability and serves as an invaluable tool for audits, compliance reviews, and incident investigations.

4. Energy Source Isolation

This is a core component of any LOTO program and is tightly integrated within the PTW workflow. The software enforces a systematic approach to energy isolation by ensuring:

- All hazardous energy sources (electrical, mechanical, hydraulic, pneumatic, thermal, chemical, etc.) are accurately identified

- Each source is physically isolated using approved lockout devices

- Verification is conducted to confirm a zero-energy state

- The entire process is documented and digitally approved before work is allowed to begin

This step is essential to prevent accidental energization, which can result in serious injury or fatalities.

By integrating LOTO procedures directly into the PTW software—with features like dual authorization, embedded checklists, digital logs, and verified energy isolation—organizations can drastically improve workplace safety, ensure regulatory compliance, and reduce operational risks across all maintenance activities.

Key Features of PTW Software for Oil & Gas Manufacturing

Customizable Permit Templates: Create templates for specific tasks like hot work, Cold Work, confined space entry, etc.

Integrated Safety Checklists: Ensures all precautions—PPE checks, atmospheric testing, LOTO procedures—are documented and verified.

Mobile Accessibility: Workers and supervisors can view or approve permits from field locations using smartphones or tablets.

Automated Workflows: Permit routing, approval, and closure follow predefined logic, reducing manual intervention and error.

Audit Trail and Reporting: Digital logs track every action taken on a permit, offering transparency and simplifying incident investigation.

Conclusion:

A Permit to Work system is very important for safety in oil and gas manufacturing. It helps control dangerous jobs, find risks, put safety steps in place, and make sure everyone talks clearly. This keeps workers and the environment safe and helps work get done better. Companies that use a good Permit to Work system show they care about safety and follow the rules. When used properly, it lowers accidents and helps create a safe work environment for everyone.